-

About Us

-

-

-

-

Language

JORSON global manufacturing, a comprehensive alternative to the era of liquid coating is coming!

According to the release of the State Administration of Market Supervision and Administration and the State Standardization Administration, the national standard "Technical Requirements for Coatings with Low Volatile Organic Compound Content", which will be officially implemented from February 1, 2021, has set strict VOC content limits for water-based coatings, wood paints, solvent-based coatings and other types of industrial protection.

Source substitution technology

The implementation of these environmental standards plays a vital role in my country's environmental protection, especially environmental indicators such as the "Ten Ring Standards", which also impose strict restrictions on government procurement projects. In addition, the future will also encourage enterprises to speed up the use of water-based, solvent-free, powder, radiation curing and other low (no) VOCs content of environmentally friendly coatings and environmentally friendly coating technology.

Encourage enterprises to speed up the use of water-based, solvent-free, powder, radiation curing and other low (no) VOCs content of environmentally friendly coatings, limit the use of solvent-based coatings. Coatings with low VOCs content shall comply with Technical Requirements for Coatings with Low Volatile Organic Compound Content (GB/T 38597-2020).

JORSON global manufacturing, a comprehensive alternative to the era of liquid coating is coming!

As a technology-driven innovative enterprise, JORSON adopts efficient and environmentally friendly coating process to promote the use of electrostatic spraying in the application of equipment in the metal packaging industry. Realize more intelligent, more environmentally friendly, more energy-saving spraying equipment to replace manual spraying, reduce the use of air spraying technology.

With the continuous development of chemical tank manufacturing technology, the parts that still need to be partially recoated are: welding ear parts, welding seam, top cover handle welding spot.

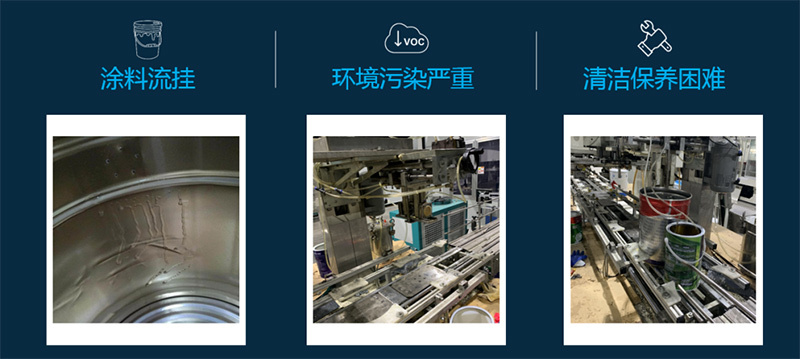

Manual brushing, gas-containing liquid spraying, printing and other traditional local coating process, resulting in paint sagging, serious environmental pollution, cleaning and maintenance difficulties and other problems are difficult to solve. Moreover, due to the strengthening of national environmental protection requirements and the improvement of customers' demand for tank quality, at the same time, the domestic metal packaging market is highly competitive, the profit space is greatly compressed, and the abnormal competition mode leads to higher and higher production costs, so it is urgent to seek new technology to reduce production energy consumption and production costs.

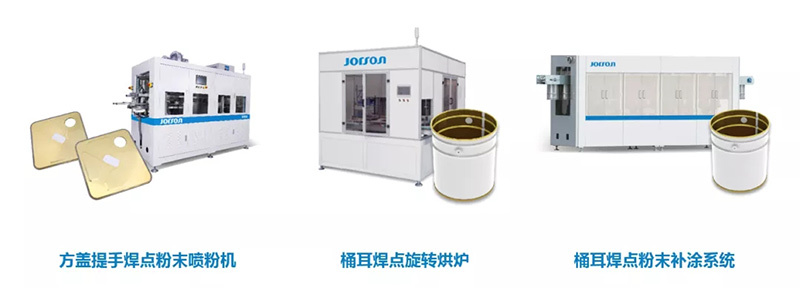

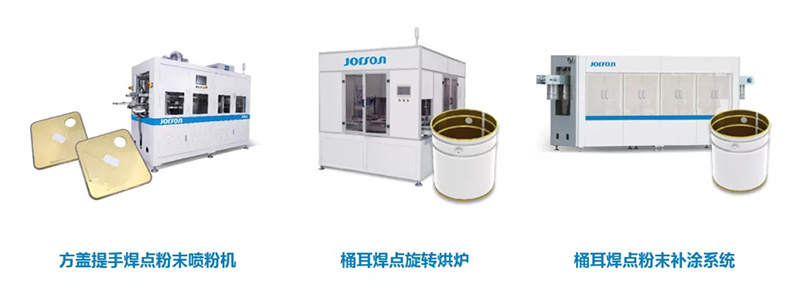

JORSON has undergone a long period of continuous research and development of the local recoating process. Now the local recoating equipment has been successfully developed and patented, the effect is significantly better than the traditional recoating process, for example, as follows:

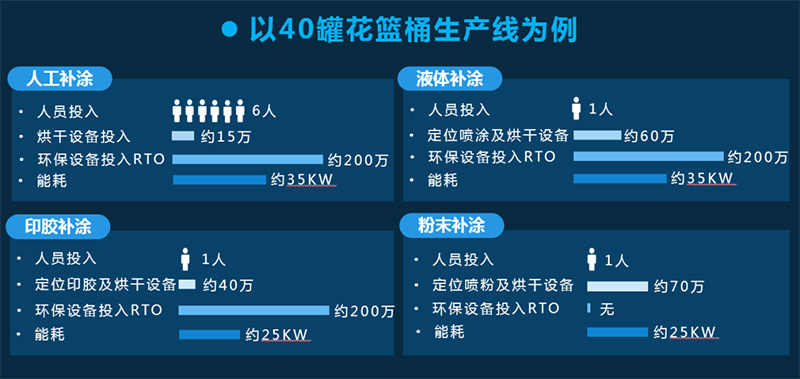

Taking the production line of 40 cans of flower basket barrel as an example, the comprehensive analysis of various aspects concludes that powder coating has obvious advantages in personnel investment and environmental protection equipment investment. That can reduce investment, but also can significantly save production energy consumption, and can achieve zero emissions of environmental benefits.

JORSON full range of environmentally friendly energy-saving powder machine products

JORSON recreates science and technology for the times, constantly innovates, and is deeply trusted and supported by customers. Adhering to the concentration, research and development exploration, excellence, with the best technology, the best service to bring each of our customers higher results, do not forget the original intention, go forward bravely.

More cases

JORSON smart machinery Co., Ltd.

JORSON Technology Co., Ltd.

JORSON Food Technology Co., Ltd.

JORSON Food (Chengdu) Co., Ltd.

Fax : 86-20-38886180

Zip Code : 511447

Add : Building 15, Innovation Science Technology Park , Shilou Town, Panyu District, Guangzhou, Guangdong, China Zip: 511447

Add : Room 903-906,Building T2,Greenland Cross-border Trade Port,No.1 guanghuabei Road 6,Qingyang District,Chengdu,Sichuan,China Zip: 610074

Copyright©2024 JORSON Technology Co., Ltd.